So I'll recap and save you the trouble of finding the leak paths etc.

First, most likely the primary leak you have is the Lubriplate on the seal faces. Seal faces are lapped to 2 light bands using a monochromatic light and an optical flat.

1.32 min video on using a monochromatic light and an optical flat on a seal face.

There is nothing smaller than 2 light bands and that includes a hydrogen molecule. Knowing that those faces are flat and nothing can get past them, you have to accept the fact that there's no lubricant lubricating the faces 'cause it just can't get in there.

You need to pull it all apart again and clean the seal faces with methyl hydrate and put back together.

The other suspect leak point I would check is the o-ring on the end of the pump shaft. Coolant could leak between the impeller and the shaft.

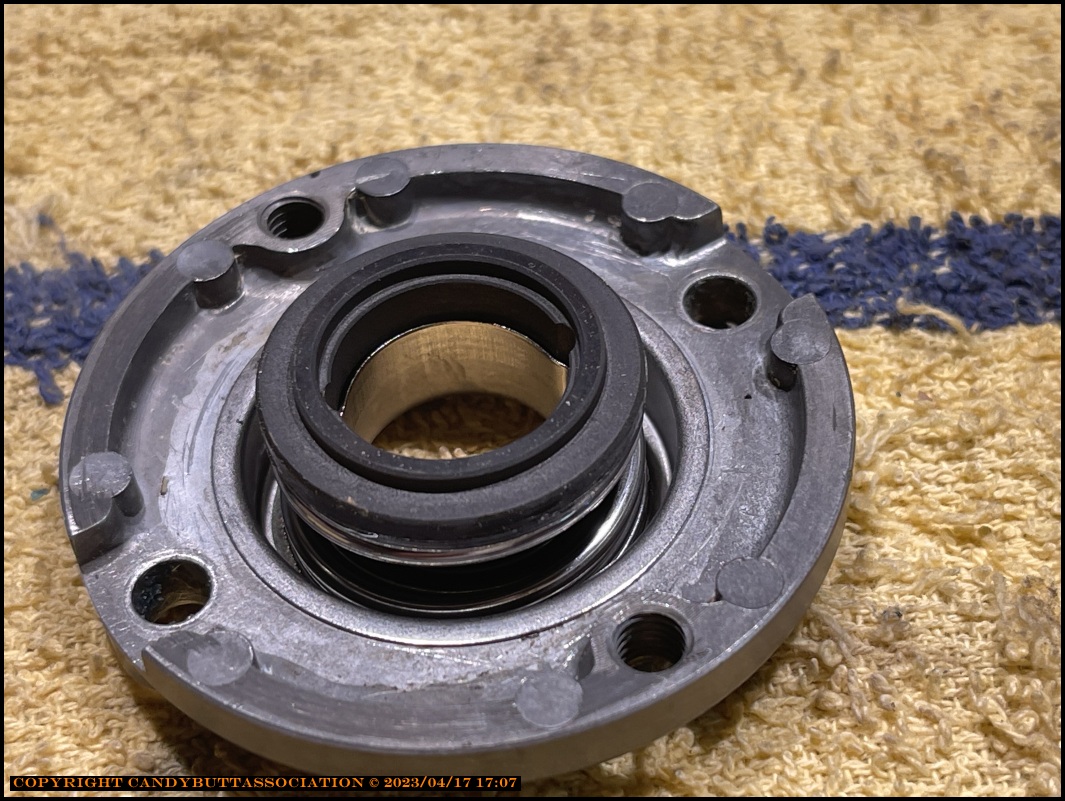

Then there's the seal point between the mechanical seal and the mechanical seal retainer. As I remember it, you heated the retainer and froze the mechanical seal then pressed it together so I'll assume you didn't put any sealer on it before assembling like RTV sealant, as per the FSM. I have a preference to Permatex High Temp RTV sealant. Never fails me and when disassembling for parts replacement, Permatex cleans off like a dream.

A millwright will tell you that when assembling a joint like this, you need to apply the sealant to both the housing and the seal, since as you press the parts together, the sealant will be pressed out of the area you're trying to seal. if you were to put the sealant on just the seal and press it in the housing, the sealant would never get in to the area you're trying to seal because the edge of the housing would scrape the sealant off.

Good luck.

KB

Thank you KB.

Still think I'll purchase 2 new seals from 2 vendors mentioned above. Have access to mono C light and optical flats. Would be interesting to see just how 'flat' both surfaces are between both sets. And make physical measurements of each seal. Just for science.

This gets me to wondering. Like an OD mic, both spindle and anvil must be parallel. Unlike an OD mic, the seal, if one surface (fixed) isn't parallel, the other (rotating) surface must adjust, via spring or coolant pressure, to ensure adequate seating and no leakage. How does one verify both seal surfaces are parallel when one is fixed, pressed into block, the other 'floating' via spring and coolant pressure when engine is warm? I would think a certain number of degree offset would be 'compensated' but after that? I can't think of any way to measure that.

O-Ring is new, but that doesn't mean squat, as per your info above. Just like the circlip, new doesn't mean correct.

I did not heat the retainer or freeze the mechanical seal then press together. Nor did I use Permatex or my favorite bonding agent when pressing the backside into the block.

Fortunately, it rained all day today (we need the water!) so I haven't been dwelling or working on this. Sometimes, my perfectionist OCD kicks in, then it's all I can think of.. resulting in over-thinking and blindness to <not seen to me> apparent clues/facts.

Thank you again. Sincerely.