Electrical

Kz1300 Ignition Health Check

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 1166

- Thanks: 243

Kz1300 Ignition Health Check

2 years 8 months ago - 2 years 8 months ago

Got to thinking about the 'popping' sound heard in exhaust, amplifed by the 6-1 DG exhaust header/muffler.

How long has it been since the ignition system was looked at?

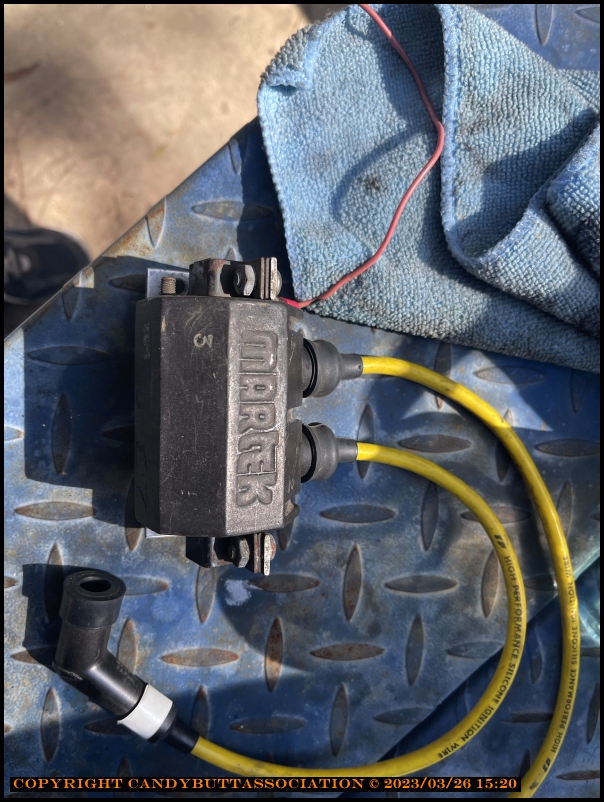

Decades ago installed 'Martek' coils and silicone wires. After doing a valve adjustment, placed all plugs on valve cover and spun the engine. #6 looked weak. Installed a new plug and it was better, but not snappy blue hot either.

And I'm pretty sure Ray just used existing parts during the rebuild process. One of the 3 coils.

Across the terminals, 2.3 ohms.

The ballast resistor measured 1.7 ohms across all three legs.Not sure if the ballast resistor should be used with Martek coils.

Found this

Hello,I just got a set of martek coils off ebay,with the instruction sheet. For road racing and normal street use,{non CDI ignitions}use only terminals 1&3.Connect the 12 volt wire to

terminal 1,connect terminal 3 to points,or electronic ignition. Cover unused terminal 2 with anything to keep it from shorting to anything. Possibly a wire nut.

Found This which indicates a hi R (3.5 ohms) does not use ballast resistor.. My primary resistance is 2.3 ohms..Brand new 12V CDI ignition coil to fit:Kawasaki (K) Z 1300 A (1979-1982).This is a high quality ignition coil, manufactured to replace any of the original coils on a Kawasaki Z1300 A1-A4 with original part numbers 21121-1019 or 21121-1017 or 21121-1018. It has 100mm mounting points and 2 spade connectors.This coil is a high output 3.5 ohm (primary) coil so you may need to remove the resistor to run these coils, they will be an upgrade to the originals that are in place using the resistor. If you are having spark issues with your KZ / Z 1300 then upgrading your coils is almost essential.If you're looking for a like for like replacement of the original coil 2 to 2.5 ohms primary, then please see our other listing

Looks like I need to determine if the Martek coils can produce hotter spark not using the ballast resistor and survive?

Decades ago installed 'Martek' coils and silicone wires. After doing a valve adjustment, placed all plugs on valve cover and spun the engine. #6 looked weak. Installed a new plug and it was better, but not snappy blue hot either.

And I'm pretty sure Ray just used existing parts during the rebuild process. One of the 3 coils.

Across the terminals, 2.3 ohms.

The ballast resistor measured 1.7 ohms across all three legs.Not sure if the ballast resistor should be used with Martek coils.

Found this

Hello,I just got a set of martek coils off ebay,with the instruction sheet. For road racing and normal street use,{non CDI ignitions}use only terminals 1&3.Connect the 12 volt wire to

terminal 1,connect terminal 3 to points,or electronic ignition. Cover unused terminal 2 with anything to keep it from shorting to anything. Possibly a wire nut.

Found This which indicates a hi R (3.5 ohms) does not use ballast resistor.. My primary resistance is 2.3 ohms..Brand new 12V CDI ignition coil to fit:Kawasaki (K) Z 1300 A (1979-1982).This is a high quality ignition coil, manufactured to replace any of the original coils on a Kawasaki Z1300 A1-A4 with original part numbers 21121-1019 or 21121-1017 or 21121-1018. It has 100mm mounting points and 2 spade connectors.This coil is a high output 3.5 ohm (primary) coil so you may need to remove the resistor to run these coils, they will be an upgrade to the originals that are in place using the resistor. If you are having spark issues with your KZ / Z 1300 then upgrading your coils is almost essential.If you're looking for a like for like replacement of the original coil 2 to 2.5 ohms primary, then please see our other listing

Looks like I need to determine if the Martek coils can produce hotter spark not using the ballast resistor and survive?

Last edit: 2 years 8 months ago by dcarver220b.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 1166

- Thanks: 243

Re: Kz1300 Ignition Health Check

2 years 8 months ago - 2 years 8 months ago

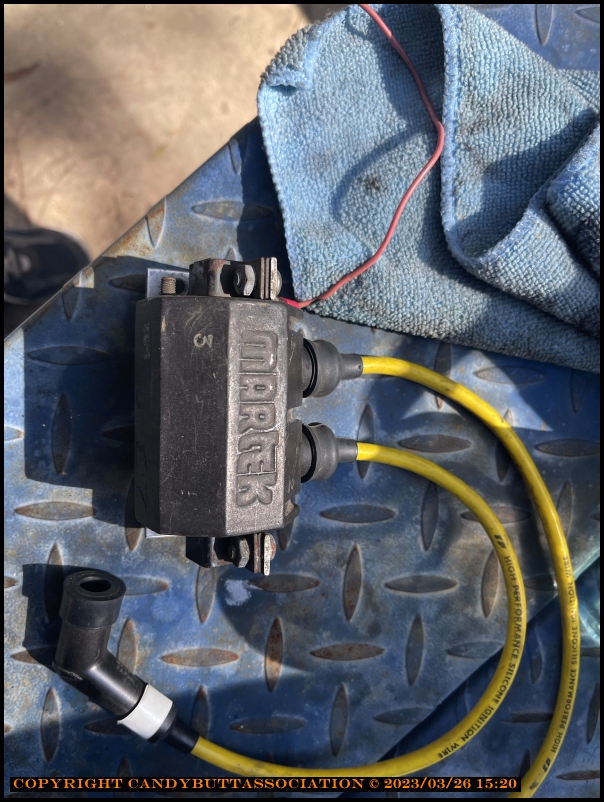

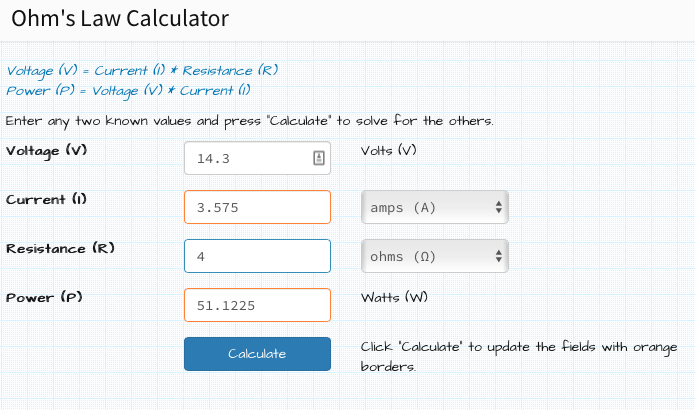

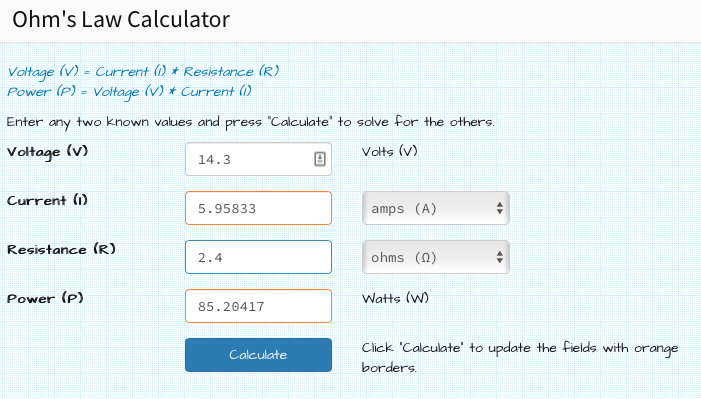

2023-03-29 Ignition Coil Primary side Current Calcs

Permalink

Submitted by

dcarver

on Wed, 03/29/2023 - 11:09. Eliminate ballast resistor?How much current allowable in primary windings of ignition coils?The Martek coils have 2.3 ohms resistance. Note I phooked up and used 2.4 ohms for below calcs. No big deal.So it's

Coil only - about right, current-wise. See post below this one...

With ballast resistor - to little current = weak spark?

- ~6 amps with out ballast resistor

- ~ 3.6 amps with ballast resistor

Coil only - about right, current-wise. See post below this one...

With ballast resistor - to little current = weak spark?

Last edit: 2 years 8 months ago by dcarver220b.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 1166

- Thanks: 243

Re: Kz1300 Ignition Health Check

2 years 8 months ago - 2 years 8 months ago

2023-03-29 Ignition Coil info from kz1300 FAQ page

Q: Can anyone tell me which color wires feed which coils for the relevant cylinders?

A: #1 & 6 - Black, #3 & 4 - Blue, #2 & 5 - Green

Q: What are the symptoms of bad ignition coils and what are my options for changing out my original coils?

A: At some point in time, the original coils start getting cracks in them and go bad. I've seen this happen on these 1300's as early as only 7000 miles! It's not the best way to go, but you can bolt on the coils from the slightly newer Kawasaki's (80' - 85') with the removable leads and a primary resistance of 2.5 ohms in the same holes as the old ones. These coils were used from 1982 to about 1989. The important thing to remember is that you remove the ballast resistor (if so equipped) so the total resistance to the CDI box is correct when installing the 2.5 ohm coils. Otherwise you’ll have problems with the primary resistance being too high. The original coils have a primary resistance of 1.5 ohms, and in conjunction with the 1.2 ohm ballast, the CDI sees 2.7+ ohms or a little more.

If the ballast goes bad and shorts out as it sometimes does with the original coils, the CDI would quickly burn up since the original coils are 1.5 ohms. Alternatively, if you use the ballast on the newer 2.5 ohm coils, the primary resistance will be 3.7+ ohms and that could damage the CDI also. The 2.5 ohm coils are a bolt on replacement for your old coils and as a bonus, they sport replaceable wires. On the original coils, you couldn’t replace just the wires as the wires are made into the coils. You will have to make up some wires to power them up with because of the different connectors, but this is a simple task. To by pass the ballast, connect the one yellow wire which is the power in, to all 3 pink wires which is power out to each coil. You can solder them all together which is best or use whatever means you must to make the connection, as long as it's a good connection.

Whatever you do with the coils the total resistance at the end of the day must be same as what you started out with. If your total resistance (coils + ballast resistor) is 2.5 ohm then you should replace with 2.5 ohm coils and bypass the ballast resistor (which is approximately 1.7 Ohm and plenty WATTS). The reason this gives better spark is that you lose almost half your voltage in the ballast resistor! Replacing it with a 2.5 ohm coil means the coil get all the voltage your CDI is putting out and gives better spark. The CDI is expecting approximately 2.7 to 3.0 ohms so make sure it doesn't change.

: some calcs : 12v and 2.5ohm = 4.8 amps (Normal)

: 12v and 3.5ohm = 3.4 amps (weak spark)

: 12v and 1.5ohm = 8 amps = fried CDI unit, but good spark while it lasts

The last example is what you get when you use stock coils, but remove the ballast resistor or the resistor goes bad. It gives almost double the amps that the CDI is made for, and although it won't let the magic smoke out immediately it will soon.

The reason we can use 2.5 to 3.0 ohm coils safely, without knowing what a schematic for the inside of the CDI may look like is that we haven't really altered anything. If we study the maintenance section of our beloved Kawasaki service manual, we will discover that their is some variance listed, but the ballast resistor has a resistance of approximately 1.3 to 1.7 ohms. Stock coils have a primary resistance of approximately 1.3. to 1.7 ohms for a total of 2.6 to 3.4 ohms, but we'd like to be at the lower range, not the higher to get the best spark output.

There really is no risk because that CDI is still reacting to the same resistance it always has and doesn't really care whether it comes from a combination of resistors and coils or just one coil. I cannot say for certain what may happen with a 3+ ohm coil, but suffice it to say the higher you get the less spark output. Your other options are to buy aftermarket coils from Dyna, Nology coils, or some other high performance coil with the appropriate ohm rating. The Accel coils are much more costly at about $80 to $120 apiece; the Dyna’s about $70 each, Nology's about $75+ each (posted prices on the net as of Nov/2004). You can check the Accel installation page for more info at - accel.zn1300.com/

Update! Until 2005 I didn't have any problems with Accel coils, but read the Accel page for current info about Accel's ohm readings measuring too high! Not a good coil for us anymore in my opinion!

Q: What is the replacement Accel coil part numbers for the 1980 KZ1300B2?

A: Accel part #'s are 140403 (2 coils) & 140403S (Single coil). The same coil for all year model KZ1300, Z1300, ZN1300, ZG1300 and Voyager 1300's. All year 1300's use the same Accel coil. On the older bikes (83' KZ1300's or older) with the original 1.5 ohm coils and ballast resistor, you simply pull the ballast off, toss it in the trash and install the coils without a ballast. On the newer year model bikes that came with 2.5 ohm coils and without the ballast, you simply mount the coils and ride.

Q: Can anyone tell me which color wires feed which coils for the relevant cylinders?

A: #1 & 6 - Black, #3 & 4 - Blue, #2 & 5 - Green

Q: What are the symptoms of bad ignition coils and what are my options for changing out my original coils?

A: At some point in time, the original coils start getting cracks in them and go bad. I've seen this happen on these 1300's as early as only 7000 miles! It's not the best way to go, but you can bolt on the coils from the slightly newer Kawasaki's (80' - 85') with the removable leads and a primary resistance of 2.5 ohms in the same holes as the old ones. These coils were used from 1982 to about 1989. The important thing to remember is that you remove the ballast resistor (if so equipped) so the total resistance to the CDI box is correct when installing the 2.5 ohm coils. Otherwise you’ll have problems with the primary resistance being too high. The original coils have a primary resistance of 1.5 ohms, and in conjunction with the 1.2 ohm ballast, the CDI sees 2.7+ ohms or a little more.

If the ballast goes bad and shorts out as it sometimes does with the original coils, the CDI would quickly burn up since the original coils are 1.5 ohms. Alternatively, if you use the ballast on the newer 2.5 ohm coils, the primary resistance will be 3.7+ ohms and that could damage the CDI also. The 2.5 ohm coils are a bolt on replacement for your old coils and as a bonus, they sport replaceable wires. On the original coils, you couldn’t replace just the wires as the wires are made into the coils. You will have to make up some wires to power them up with because of the different connectors, but this is a simple task. To by pass the ballast, connect the one yellow wire which is the power in, to all 3 pink wires which is power out to each coil. You can solder them all together which is best or use whatever means you must to make the connection, as long as it's a good connection.

Whatever you do with the coils the total resistance at the end of the day must be same as what you started out with. If your total resistance (coils + ballast resistor) is 2.5 ohm then you should replace with 2.5 ohm coils and bypass the ballast resistor (which is approximately 1.7 Ohm and plenty WATTS). The reason this gives better spark is that you lose almost half your voltage in the ballast resistor! Replacing it with a 2.5 ohm coil means the coil get all the voltage your CDI is putting out and gives better spark. The CDI is expecting approximately 2.7 to 3.0 ohms so make sure it doesn't change.

: some calcs : 12v and 2.5ohm = 4.8 amps (Normal)

: 12v and 3.5ohm = 3.4 amps (weak spark)

: 12v and 1.5ohm = 8 amps = fried CDI unit, but good spark while it lasts

The last example is what you get when you use stock coils, but remove the ballast resistor or the resistor goes bad. It gives almost double the amps that the CDI is made for, and although it won't let the magic smoke out immediately it will soon.

The reason we can use 2.5 to 3.0 ohm coils safely, without knowing what a schematic for the inside of the CDI may look like is that we haven't really altered anything. If we study the maintenance section of our beloved Kawasaki service manual, we will discover that their is some variance listed, but the ballast resistor has a resistance of approximately 1.3 to 1.7 ohms. Stock coils have a primary resistance of approximately 1.3. to 1.7 ohms for a total of 2.6 to 3.4 ohms, but we'd like to be at the lower range, not the higher to get the best spark output.

There really is no risk because that CDI is still reacting to the same resistance it always has and doesn't really care whether it comes from a combination of resistors and coils or just one coil. I cannot say for certain what may happen with a 3+ ohm coil, but suffice it to say the higher you get the less spark output. Your other options are to buy aftermarket coils from Dyna, Nology coils, or some other high performance coil with the appropriate ohm rating. The Accel coils are much more costly at about $80 to $120 apiece; the Dyna’s about $70 each, Nology's about $75+ each (posted prices on the net as of Nov/2004). You can check the Accel installation page for more info at - accel.zn1300.com/

Update! Until 2005 I didn't have any problems with Accel coils, but read the Accel page for current info about Accel's ohm readings measuring too high! Not a good coil for us anymore in my opinion!

Q: What is the replacement Accel coil part numbers for the 1980 KZ1300B2?

A: Accel part #'s are 140403 (2 coils) & 140403S (Single coil). The same coil for all year model KZ1300, Z1300, ZN1300, ZG1300 and Voyager 1300's. All year 1300's use the same Accel coil. On the older bikes (83' KZ1300's or older) with the original 1.5 ohm coils and ballast resistor, you simply pull the ballast off, toss it in the trash and install the coils without a ballast. On the newer year model bikes that came with 2.5 ohm coils and without the ballast, you simply mount the coils and ride.

Last edit: 2 years 8 months ago by dcarver220b.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 1166

- Thanks: 243

Re: Kz1300 Ignition Health Check

2 years 8 months ago - 2 years 8 months ago

Okay, here we go again.

As per the Service Manual

Resistance in a series circuit (which is the primary circuit in the ignition) is the addition of the resistances of the components in the circuit so in this case. if we add the resistance of the ballast resistor to the resistance of the primary winding of the ignition coil we get 1.5 to 1.9 ohms + 1.2 to 1.9 ohms we get a range of 2.7 to 3.8 ohms total primary circuit resistance permissible to be within Service Spec.

Ohms Law states that Amperage = Voltage divided by Resistance so bearing in mind that the charging voltage of a running KZ1300 averages around 14.5 volts we can work out the amperage of the primary circuit.

14.5 volts / 2.7ohms = 5.37 amps

14.5 volts / 3.8 ohms = 3.81 amps

The service limits as spec'd in the Service Manual basically states that we can run up to 5.37 amps in the primary circuit and this will not damage the control switches in the circuit which are the Darlington transistors in the igniter.

So, as long as the resistance in the primary ignition circuit is maintained above 2.7 Ohms you should be fine. The only caution here from my point of view is that you would be running really tight to the maximum amperage that the Darlington's can handle and there would be no room for error.

I do remember that Trikbldr got in to this topic years ago and started explaining all the electronic theory regarding this primary circuit topic and he was adamant that "some additional resistor was required to dampen the (for the sake calling it something) reverberation of the voltage fluctuations in the primary circuit to protect the Darlington transistors. Trikebldr got really upset at members on this site referring to him as a blowhard and Trikebldr left us to our own demise and tootled off to his other favorite site American Voyagers Association since it was more in tune with his desires

As per the Service Manual

Resistance in a series circuit (which is the primary circuit in the ignition) is the addition of the resistances of the components in the circuit so in this case. if we add the resistance of the ballast resistor to the resistance of the primary winding of the ignition coil we get 1.5 to 1.9 ohms + 1.2 to 1.9 ohms we get a range of 2.7 to 3.8 ohms total primary circuit resistance permissible to be within Service Spec.

Ohms Law states that Amperage = Voltage divided by Resistance so bearing in mind that the charging voltage of a running KZ1300 averages around 14.5 volts we can work out the amperage of the primary circuit.

14.5 volts / 2.7ohms = 5.37 amps

14.5 volts / 3.8 ohms = 3.81 amps

The service limits as spec'd in the Service Manual basically states that we can run up to 5.37 amps in the primary circuit and this will not damage the control switches in the circuit which are the Darlington transistors in the igniter.

So, as long as the resistance in the primary ignition circuit is maintained above 2.7 Ohms you should be fine. The only caution here from my point of view is that you would be running really tight to the maximum amperage that the Darlington's can handle and there would be no room for error.

I do remember that Trikbldr got in to this topic years ago and started explaining all the electronic theory regarding this primary circuit topic and he was adamant that "some additional resistor was required to dampen the (for the sake calling it something) reverberation of the voltage fluctuations in the primary circuit to protect the Darlington transistors. Trikebldr got really upset at members on this site referring to him as a blowhard and Trikebldr left us to our own demise and tootled off to his other favorite site American Voyagers Association since it was more in tune with his desires

Last edit: 2 years 8 months ago by dcarver220b.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 1166

- Thanks: 243

Re: Kz1300 Ignition Health Check

2 years 8 months ago

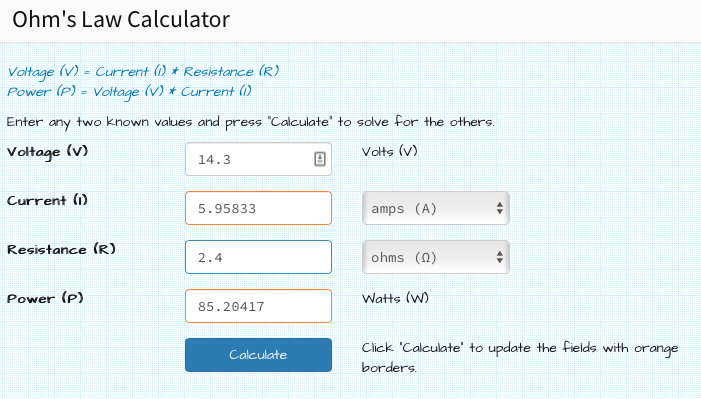

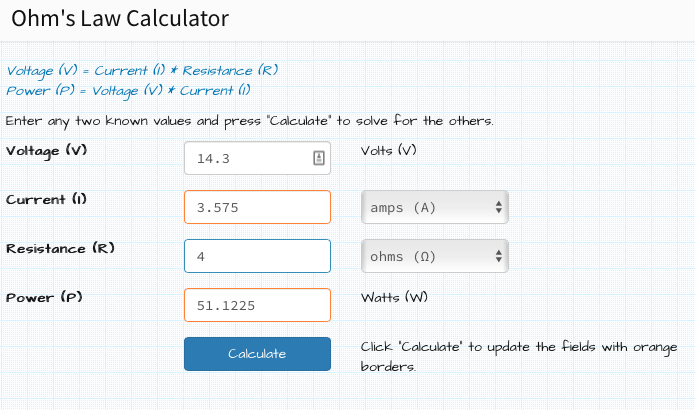

"The CDI is expecting approximately 2.7 to 3.0 ohms so make sure it doesn't change."

- Presently, primary resistance is 4 ohms (1.7 ballast + 2.3 coil), excessive

- If all three ballast resistors are configured for parallel, resistance drops to 0.57 Ohms

- Overall resistance is then 2.3 (coil) + 0.57 (new ballast R) = 2.87 Ohms

- 2.87 Ohms is a smack-dab between 2.7 and 3.0 Ohms

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 1166

- Thanks: 243

Re: Kz1300 Ignition Health Check

2 years 8 months ago - 2 years 8 months ago

2023-03-30 Good Ignition Coil Replacement Post on KZ1300.com

Found this really good post on KZ1300.com

Found this really good post on KZ1300.com

Last edit: 2 years 8 months ago by dcarver220b.

Please Log in or Create an account to join the conversation.

Time to create page: 0.836 seconds